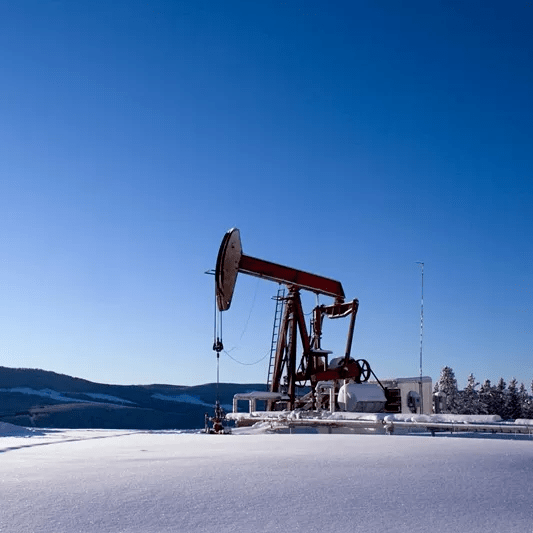

SUNRISE PETRO, established in 1964, is a comprehensive enterprise integrating design, R & D, manufacturing and oilfield services. SUNRISE PETRO overall floorage is more than 600,000 square meters with more than 1200 advanced equipments and 1,500 employees. SUNRISE PETRO has 18 production plants, 12 subsidiaries and several offices around the main oilfield in the world.

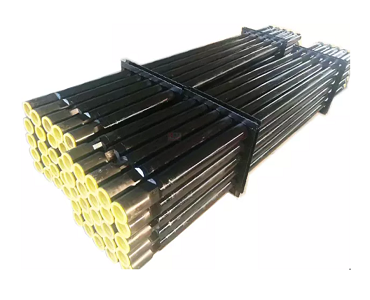

Diversified business covers seven blocks: conventional drilling & recovery equipment, complete sets of thermal recovery equipment, anti-corrosion and anti-abrasion solution, multiphase flowmeter solution, Automatic workover system, tertiary oil recovery,oil and gas mixed transportation equipment. Products are exported to North America, South America, Asia, Middle East, Africa, CIS and other regions. Sales value is $150 million per year. SUNRISE PETRO has obtained 178 national patents and international certificates, including ISO9001, HSE, ASME, CE, PR2 and etc.Get a free quote now!