Sucker rod and accessories Development

The sucker rod is an important part of the sucker rod pumping equipment, which transfers the power of the pumping unit to the downhole pump.

The sucker rod string is composed of dozens or hundreds of sucker rods connected by couplings.

In the process of oil production, the sucker rod string bears the action of asymmetric cyclic load, and the working medium is well fluid (crude oil and ore water), while the well fluid of many pumping wells contains corrosive medium.

Therefore, the main failure mode of sucker rod is fatigue fracture or corrosion fatigue fracture.

The accident of sucker rod breaking will seriously affect the crude oil production, increase the workover cost and increase the crude oil cost.

Sucker rod has a history of nearly one hundred years.

The most original brine sucker is made of rattan.

The first patent for metal sucker rod (U.S. 528168) was obtained by Samuel M. Jones in Ohio on October 30, 1894.

In the past 20 years, many new materials, new equipment, new technologies and new processes have been used in the manufacture of sucker rods at home and abroad, such as multi-element alloy steel and glass fiber reinforced plastic;

Medium frequency induction heating equipment and automatic flat forging machine are used for forging, medium frequency induction heating and quenching device and infrared light guide intelligent temperature measuring instrument are used, non rotating processing production line of sucker rod head and automatic coupling production line are used;

As well as advanced forging die design technology, external thread rolling process of sucker rod, half cutting and half extruding process of internal thread of coupling, friction welding process, shot peening strengthening process, surface induction quenching process, etc., the manufacturing level and product quality of sucker rod have been greatly improved.

In order to meet the needs of large pump forced production, small pump deep pumping, heavy oil well, high wax well, corrosion well and inclined well oil production, many special sucker rods have been developed at home and abroad, such as ultra-high strength sucker rod, glass fiber reinforced plastic sucker rod, hollow sucker rod, KD grade sucker rod, continuous sucker rod, electric heating sucker rod, wire rope sucker rod and aluminum alloy sucker rod, and many matching parts of sucker rod string have been studied, such as long stroke high-strength polished rod The toothless polished rod clip, rotary rod device, shock absorber, graphite adjustable center polished rod seal box, roller coupling, centralizer, wax scraper, weighting rod, anti stripping device, stripper, magnetic wax preventer and pump air controller further improve the service life and application range of the sucker rod.

Structure and application

Sucker rod is an important part of sucker rod pumping equipment.

The sucker rod is connected into a sucker rod string through a coupling.

The upper part is connected to the pumping unit through a polished rod, and the lower part is connected to the plunger of the oil well pump.

Its function is to transmit the reciprocating motion of the horsehead suspension point of the surface pumping unit to the downhole oil well pump.

The failure of sucker rod thread is often shown as the pulling of the thread.

However, due to the lower concave design of the thread of modern API sucker rod and the use of rolling instead of turning when manufacturing the thread, such problems have been greatly reduced.

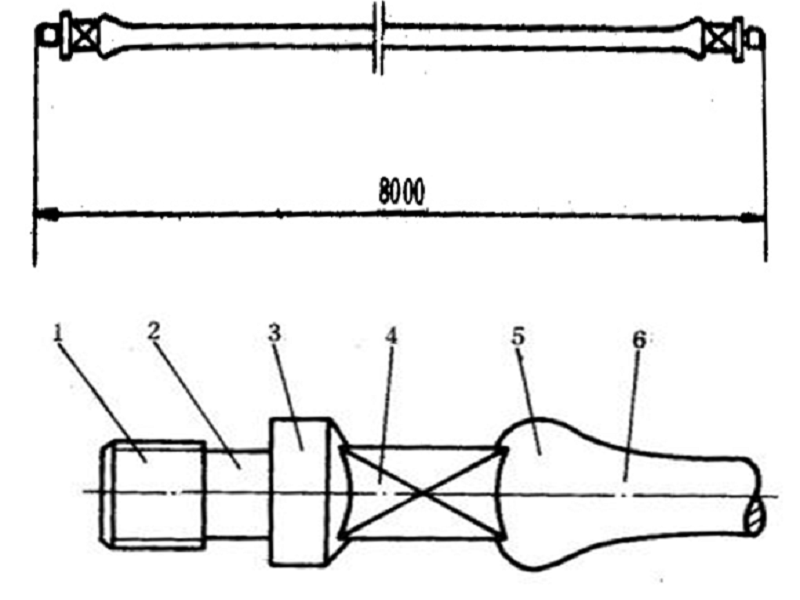

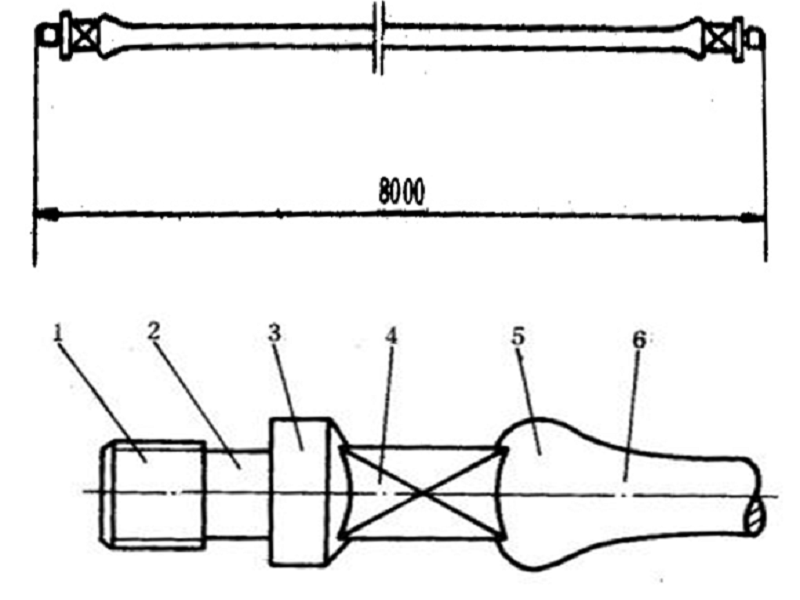

The structure of common sucker rod and its head is shown in the figure below.

The rod body is a steel rod with solid circular section, and the two ends are upset rod heads.

The rod head is composed of external thread joint, unloading groove (stress dispersion groove), shoulder of push bearing surface, square diameter of wrench, flange and arc transition area.

The external thread joint is used to connect with the coupling, and the square neck of the wrench is used to clamp the sucker rod pliers when loading and unloading the sucker rod joint.

1.External thread joint 2.Stress dispersion groove 3.Bearing shoulder

4.Wrench square diameter 5.Flange 6.Arc transition area

According to API standards, the rod diameters of sucker rods are usually 12.7 (1/2in), 15.9mm (5/8in) and 19.1mm (3/4in); 22.2mm(7/8in); 25.4mm(1in); 28.6mm(1 1/8in).

The length of sucker rod is generally 8000mm or 7620mm. In order to adjust the length of the sucker rod string, there is also a short sucker rod with a variety of length.

API SPEC 11B Sucker Rods and Chinese SY/T 5029-2005 classify common sucker rods into three grades: Grade C, Grade D and Grade K. Grade C sucker rod is used for light and medium load oil wells, Grade D sucker rod is used for medium and heavy load oil wells, and Grade K sucker rod is used for light and medium load and corrosive oil wells.

Grade C, D and K sucker rods are made of carbon steel or manganese steel, carbon steel or alloy steel, and nickel molybdenum alloy steel, which are generally subject to upsetting, overall heat treatment, external thread rolling, shot peening strengthening, oil soluble coating protection and other processes to obtain certain fatigue resistance or corrosion fatigue resistance.

In order to meet the needs of high water cut, high viscosity, high freezing point, high wax content pumping wells, corroded wells, deep wells and inclined wells for crude oil exploitation, many special sucker rods with different structures, materials and uses from ordinary sucker rods have been developed at home and abroad in the past 20 years, such as ultra-high strength sucker rods, glass fiber reinforced plastic sucker rods, hollow sucker rods and continuous sucker.