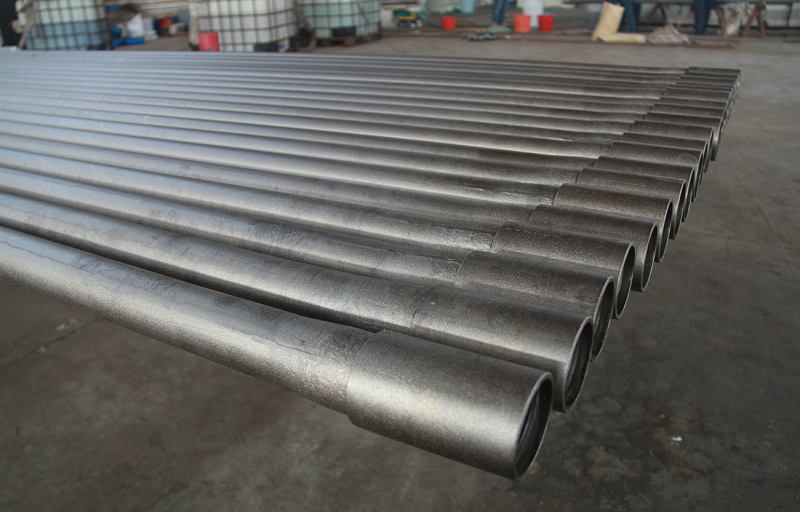

With the increase of working time, conventional sucker rods are prone to corrosion and eccentric wear during operation, and are not suitable for high-strength or harsh working conditions. To solve the eccentric wear and corrosive problems in oilfields, Sunrise Petro developed various anti-corrosion and anti-abrasion products, including tungsten-plated sucker rod.

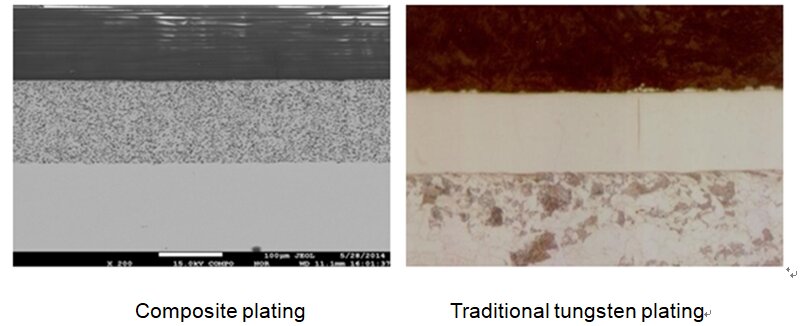

After two years of dedicated research and development, Sunrise Petro has successfully developed a new type of nickel tungsten composite plating technology, which is widely used for surface treatment of tungsten-plated sucker rod. Composite plating is to add insoluble particles (such as ceramic particles) to the plating solution on the basis of electroplating and electroless plating, so that the particles are deposited together with the coating, and the coating has the characteristics of both metal coating and particles.

We adopted advanced fourth-generation nickel-based tungsten plating technology. Compared with conventional anti-corrosion methods such as liner and internal spraying, tungsten plating has the characteristics of high hardness, high anti-corrosion, strong coating adhesion, and high working temperature.

Based on the advanced nickel-based technology, Sunrise Petro composite plated products take the lead in China.

The following is the metallographic comparison of composite plating(left) and traditional tungsten plating(right).

The following is Sunrise Petro composite plating data sheet.

| Item | Parameter | Standards |

| Thickness | ≥40μm | GB/T11354 |

| Hardness | 450~550HV | GB/T9790 |

| CASS Test(Copper-accelerated acetic acid salt spray) | no discoloration, pitting, cracks in 96 hours | GB/T10125 |

Features

1) High wear resistance. The hardness of the coating is 940-1100hv, and the wear resistance of the coating is greatly increased, which is far better than the chromium coating.

2) High anti-corrosion. Ni-W alloy has excellent corrosion resistance which leads the coating has no pinholes and microcracks to increase the protection ability.

3) Strong coating and plating adhesion

4) The max working temperature can reach 300℃.

Application

The tungsten-plated sucker rod of Sunrise Petro is especially suitable for high water cut oil wells with high corrosion and prone to eccentric wear.

Sunrise Petro can supply API Sucker rod including the common sucker rod& pony rod, polished rod and tungsten-plated sucker rod. Based on API Spec 11B and SY / T 5029 specifications, Sunrise Petro also developed a series of special sucker rods suitable for different well conditions, especially under high corrosion and high load conditions for oil well. .

Our technical staff is ready to provide assistance in selection and design.With inventory and field sales support in strategic location, we are ready to respond in a timely professional manner 24 hours a day..