The metering pump

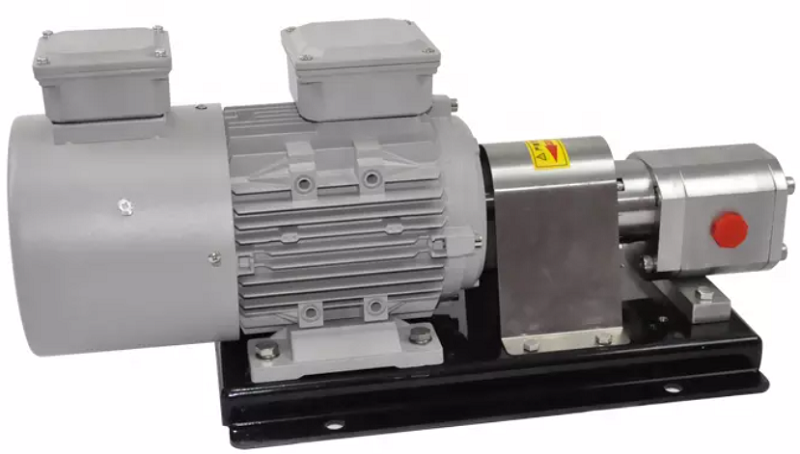

The metering pump is a special positive displacement pump used to transport liquids. Now it has been widely used in petrochemical, oilfield, food and other industrial fields. It can meet the needs of strict processes. The flow can be adjusted within the range of 0-100%.

Due to the need of precise control and measurement, metering pumps are divided into multiple types and have multiple parameters. Therefore, users should pay more attention when selecting and using metering pumps.

Let’s take a deep look at the following precautions about metering pump. This will make you get twice the result but with half the effort.

Metering accuracy

Metering accuracy is the most basic parameter of metering pump, and users should pay attention to this before purchasing.

According to Chinese national standard GB/T 7782 Metering Pump, the flow metering accuracy of the pump under rated conditions and at the maximum relative stroke length shall not be less than ± 1%.The best range of the pump’s flow metering accuracy is more than 30%. When the application range required by the process flow is ≤ 10%, the stroke adjustment and frequency conversion parallel adjustment can be used to solve the problem.

Installation height (from pump head center to liquid level)

When selecting metering pumps, users should pay attention to the installation and operation conditions on the site.

Generally speaking, for normal temperature medium conveying physical properties similar to clean water, the installation height of plunger pump is ≤ 6m, the installation height of hydraulic diaphragm pump is ≤ 4.5m, and the installation height of mechanical diaphragm pump is ≤ 3m. For pumps with flow less than 50L/H, it is recommended that the process flow be arranged in reverse flow mode.

Flexibility

When comparing different models of metering pumps, the client should check out the flexibility, which means to alter the function of the metering pump to suit changing requirements. One of the major flexible parameters is flow regulation. The metering pump can accurately add liquid and strictly control the flow, so flow regulation is an important part of the flow pump.

Flow regulation usually adopts the following methods:

- Change the stroke length of the plunger (diaphragm) of the pump (the optimal relative stroke length is 30%~100%), and the regulation can be carried out during shutdown or operation.

- Use a frequency converter to change the input power frequency to adjust the pump speed, or install an intelligent stroke controller and a digital controller to facilitate automatic control and computer program control of flow regulation. 3. The stroke adjustment and frequency conversion are in parallel to expand the effective adjustment range of the pump.

Safety and durability

For oilfield production or other projects, the safety accident of metering pumps would delay production measurement or even cause other unnecessary troubles. Here shows some advice to avoid such problems.

Check the reliability of metering pump before purchase. All parts of the equipment shall be well assembled, intact and free from any signs of refurbishment, unless specifically required.

Check transmission medium temperature. For common metering pumps on the market, the medium tolerance temperature of plunger pump can reach – 50 ℃~350 ℃, while that of diaphragm pump is slightly narrow, about – 30 ℃~280 ℃.

Check the corrosion resistance of metering pump, especially for the medium-passing component. The corrosiveness and PH value of different measuring media is not the same. The better corrosion resistance a pump has, the more media a pump measures.

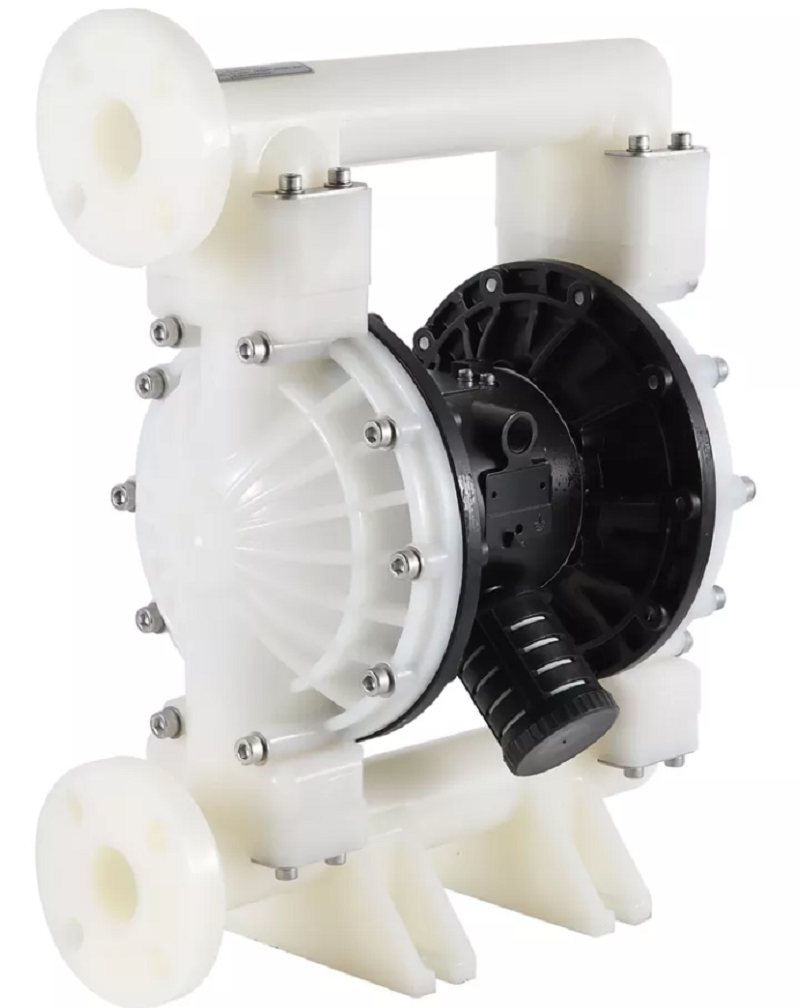

Ensure no leakage of the medium during operation. Diaphragm metering pump is recommended when measuring unconventional liquid. The hydraulic end and the power end are separated safely through the diaphragm to ensure zero leakage of the medium. It is suitable for conveying flammable, explosive, highly toxic, precious and other liquids. Clients can also choose double diaphragm metering pump with diaphragm rupture alarm device to further improve the level of prevention and ensure safety.

For metering pump pipeline system

The metering pump is often used together with the pipeline system. In order to ensure smooth operation, the following points should be noted.

- To ensure the safety of the pump and pipeline system, a safety valve should be set on the outlet pipeline.

- In order to smooth the flow pulsation of the metering pump, a buffer can be set at the outlet of the pump or a multi head metering pump can be used.

- When the pressure difference between inlet and outlet is too low, a back pressure valve shall be set on the outlet pipeline.

- To ensure the flow metering accuracy, the inlet pipeline shall be installed with a filter.

- In order to facilitate the calibration of the flow of the metering pump, a flow calibration tube can be installed in the inlet pipeline.