The sucker rod with clamping protects bush

At present, the anti-wear and anti-corrosion sucker rod is made of common sucker rod by outer wall coating, injection molding or outer wall plating. It has high anti-corrosion performance for various corrosive media to extend service life and reduces the operation cost. However, one disadvantage is during sucker rod unloaded, the anti-corrosion layer at the wrench square will be bitten by the wrench, exposing the sucker rod body. This leads to local corrosion of the sucker rod when downhole operation and reduce the service life.

To solve this problem, Sunrise Petro invented one kind of anti-abrasion and anti-corrosion sucker rod with a clamping protecting bush. When connecting or removing the sucker rod, the wrench locks the clamp protective bush to avoid partial concentration of the sucker rod corrosion causing failure and prolongs the using life of external anti-corrosion sucker rods.

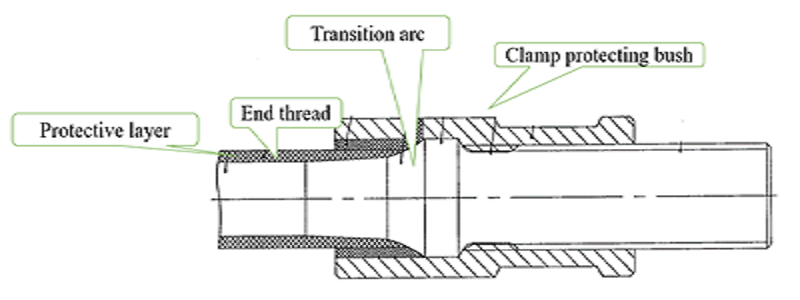

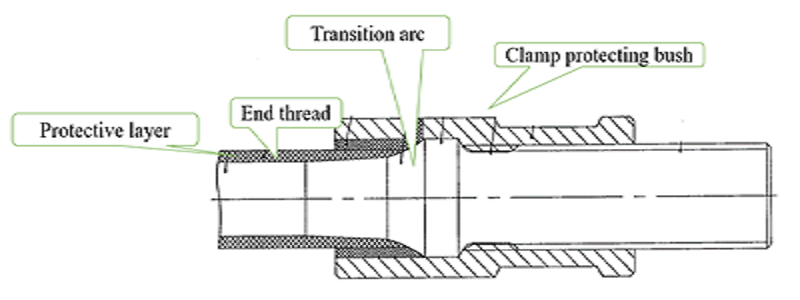

The anti-abrasion and anti-corrosion sucker rod with clamp protecting bush is mainly composed of the rod body, protective layer and end threads, as shown in the following figure:

- Protective layer; 2. End thread; 3. Transition arc; 4.Clamp protective bush;

The main working principle of the anti-abrasion and anti-corrosion sucker rod with clamp protective bush is as follows: the end thread is provided with a clamp protective bush matched with it, and the gap between the clamp protective bush and the rod body is filled with stuffing, the filler is a non-metallic anti-corrosion material, there is a overflow hole on the clamp protective bush, after the filler is completely filled, the overflow and flash are removed, and there is a thickened end between the thread on the end of the sucker rod and the rod body.

There is a relief groove between the thread and the thickened end, there is a transition arc between the thickened end and the rod body, the clamp protective bush is screwed on the thread end, and the exposed part of the end thread can be connected with the conventional sucker rod coupling connection, apply sealing material before screwing buckle the clamp protective bush with sucker rod end thread to prevent liquid from entering the thread gap and causing corrosion.

The gap between the transition arc of the protective bush and the sucker rod is filled with stuffing to ensure that there is no bare place on the sucker rod body at the transition arc.

When loading and unloading the coupling, the wrench is clipped on the clamp protective bush, which can prevent the anticorrosion layer at the sucker rod outer anticorrosion layer is bitten by the wrench.

The anti-abrasion and anti-corrosion sucker rod with clamp protective bush has simple structure and is convenient to manufacture.

It can avoid the bite of the anti-corrosion layer at the side of the sucker rod wrench during operation, which can greatly improve the anti-corrosion ability of the outer anti-corrosion layer and extend the sucker rod using life.