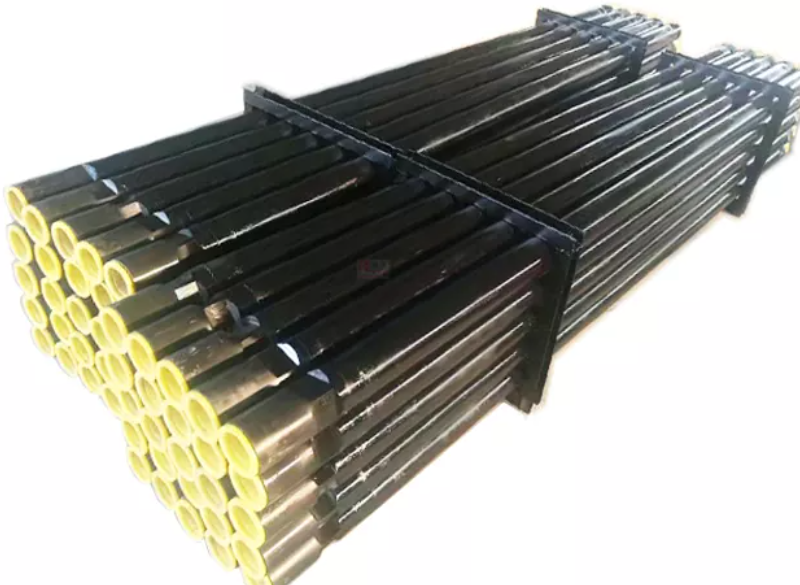

The drilling pipe

The drilling pipe is the basic component of the drill string, which is mainly used to transmit torque, convey drilling fluid, and continuously connect the drill tools. As a result, the drilling pipe plays an important role in the drilling process. If one company could purchase the drilling pipe with the highest quality and cost performance, the company would effectively reduce procurement cost and improve drilling production efficiency.

The following article may give you some advice about how to choose an excellent drilling pipe supplier.

First, complete certificates

Drilling pipe production is a standardized industry. There exist a few widely recognized certificates to prove the production capability and product quality. Before purchasing any drilling pipe, you must check the certificates of the supplier firstly. Necessary drill pipe certificates are generally divided into two types: product certificates, including API 5DP and API 7-1 certificates, and quality management system certificates, including API Q1, ISO 9001 and ISO 14001 certificates.

Today, API standard is the most authoritative and universal petroleum equipment standard in the international market. So any supplier should get both two types certificates to prove its design, production and quality control can meet the requirements of API standards and trustworthy.

In addition, the buyer should check how many years the supplier has obtained the API certificate and whether there is a record of deactivation. Long time of continuous API certification shows the drilling pipe supplier is dependable. All of this information can be found conveniently on the API website.

Second, well-appointed production equipment

Drilling pipe production is a comprehensive process. There are many processes involved, including welding, lathe machining, end upsetting, heat treatment, assembly, flaw detection, spraying and other procedures. The whole operation needs various machines such as CNC, upsetting machining, heat treatment equipment, ultrasonic flaw detection instrument and others.

If the supplier has complete production equipment, it can cover the whole production process with the quality management system and can control the product quality and delivery time better. Quality and delivery time are significant to buyers.

Third, strict quality control

To ensure smooth drilling production, the drilling pipe requires reliable quality which means low failure rate. Quality control must occupy the first place in drilling pipe production.

Relevant quality control has mainly two parts. First, a comprehensive quality management system must be established. The supplier shall strictly implement APIQ1 standard for quality control. This can be verified by checking certificates and quality control documents of the supplier. The second is to have a complete set of quality inspection equipment. The supplier shall own the raw material inspection equipment, process inspection equipment, measuring tools, complete drilling pipe test equipment, and ensure that the inspection equipment is regularly checked and measured accurately as well. Factory inspection can be conducted on site or online by TPI.

Fourth, integrated after-sales service network

Working environment of the drilling pipe may be really serious. If any problem occurs during operation, the supplier shall be able to provide timely and efficient after-sales service to help the client deal with the problem ASAP. Such as restore the drilling pipe operation, shorten the downtime caused by the drilling pipe fault, and reduce client loss finally. The after-sales service capability can be reflected by the scale of its overseas after-sales service institutions and service personnel.

Any client should pay attention to the four aspects above before drilling pipes procurement. If one supplier has notable advantages in these aspects, it means the supplier is creditable of drilling pipe production.